CUSTOM APPLICATIONS

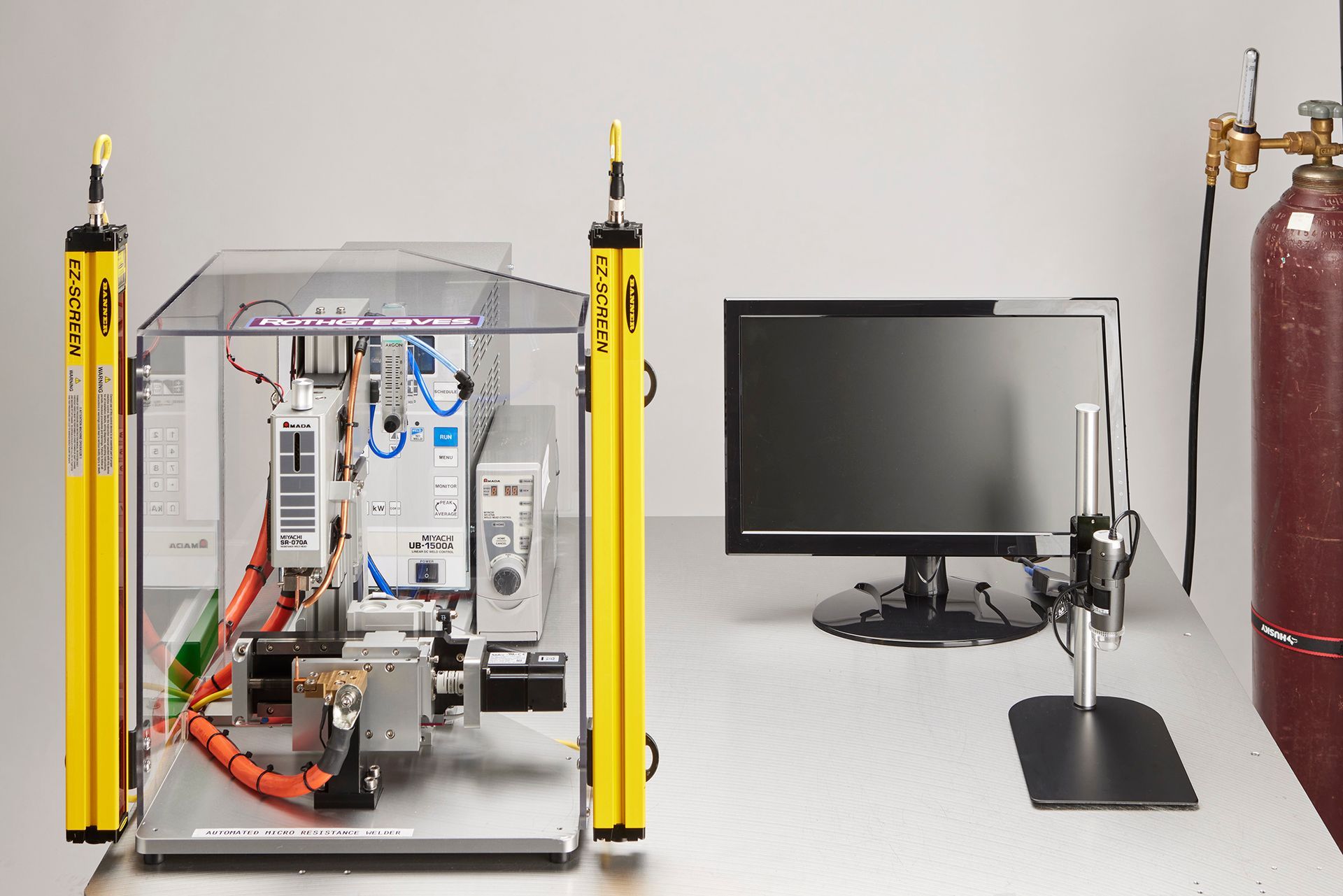

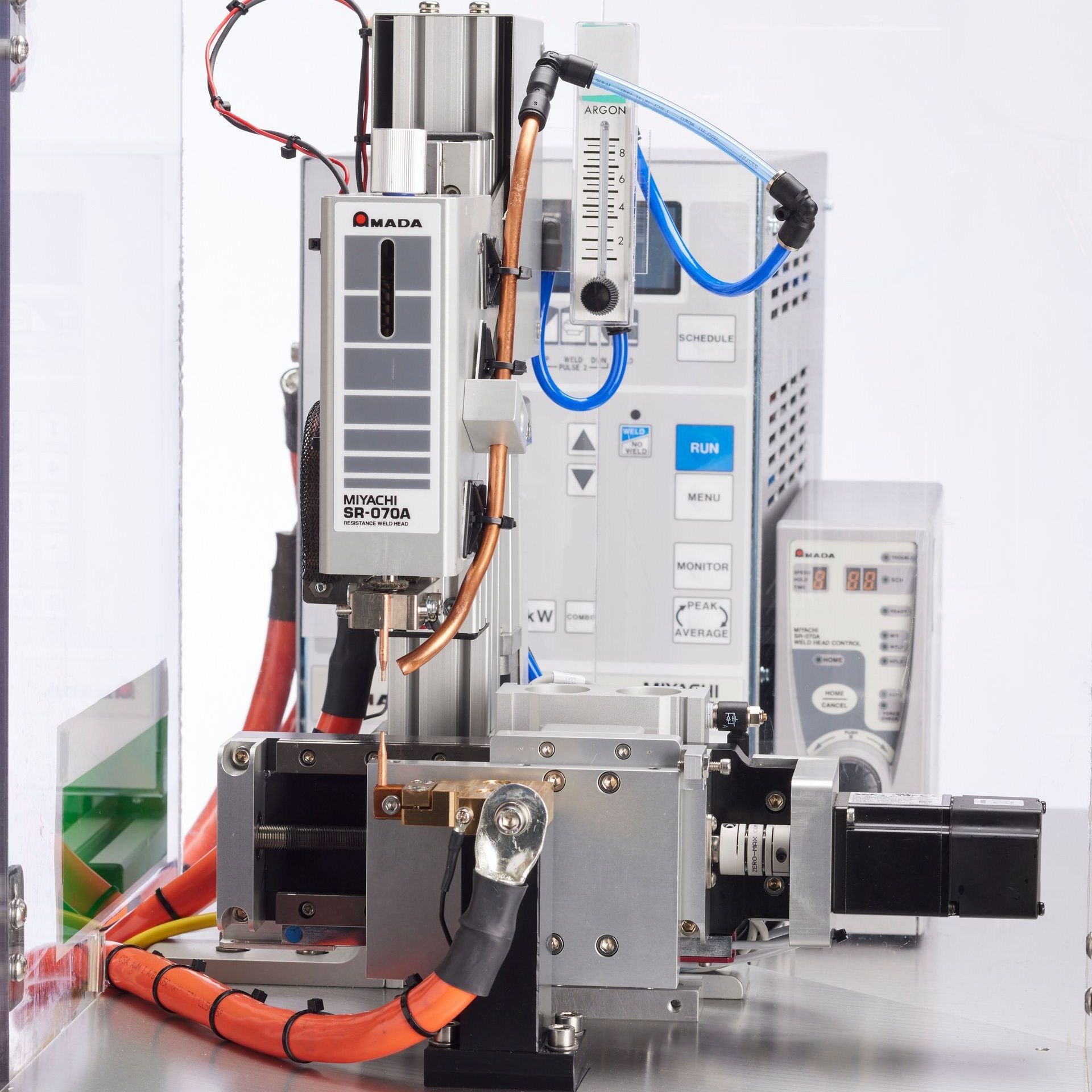

Automated Micro Resistance Spot Welder

Project Challenge

A client needed a compact, high-precision welding system capable of handling small, intricate components with multiple weld configurations. The solution had to support quick part changeovers, enable offline loading for improved efficiency, and integrate safety and inspection features to ensure consistent quality. Key Challenges included:

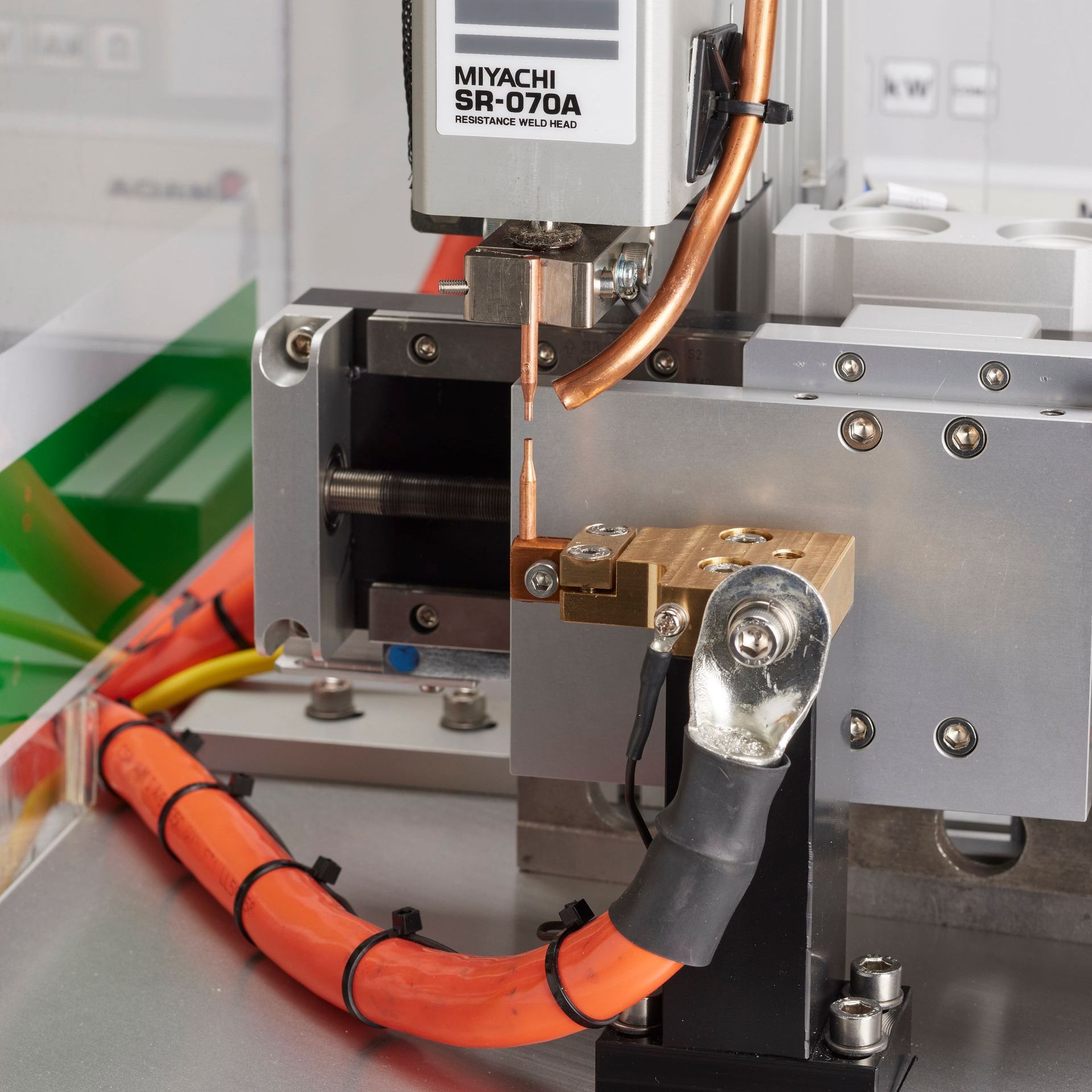

- Required welding methods: opposed (step, series, and seam also available)

- Demanded precise, repeatable welds with tight tolerances

- Needed tooling that could be swapped quickly to reduce downtime

Rothgreaves solution

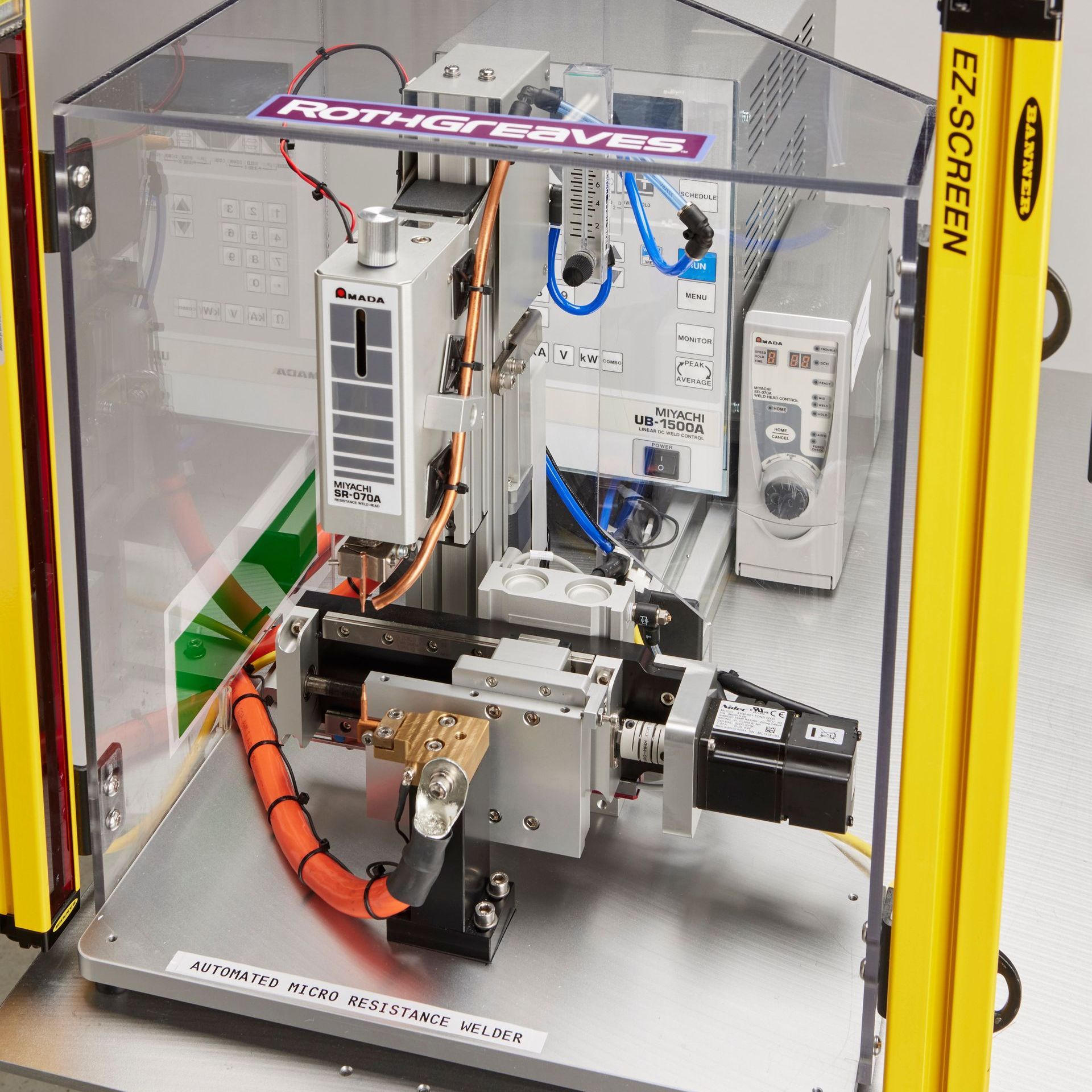

RothGreaves delivered the Automated Micro Resistance Spot Welder—a PLC-controlled, servo-driven system designed for both accuracy and flexibility. Operators can load parts offline into custom nests, then quickly insert them into the machine using a quick-change tooling base. Safety is built in with a light curtain and emergency stop, while optional inspection and pull test fixtures help validate every weld. Main Features include:

- Quick-change tooling base with custom piece part nests

- Custom weld schedule development and programming

- Industry-leading weld head and power supply for consistent results

- Optional shielding gas and inspection fixtures to ensure quality

Automated Micro Resistance Spot Welder featured Pictures

Supporting Medical Device Manufacturing Around the World

All Rights Reserved | RothGreaves