ptfe coatings

Polytetrafluoroethylene DRy release COATINGS by rothgreaves

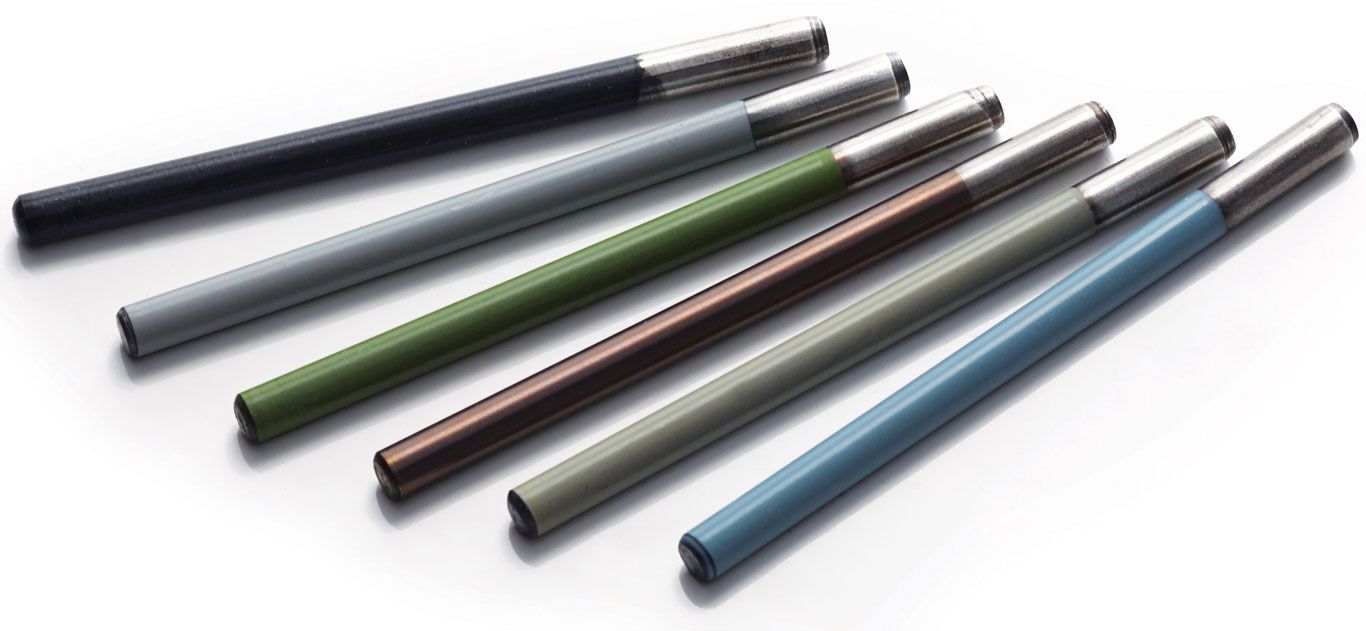

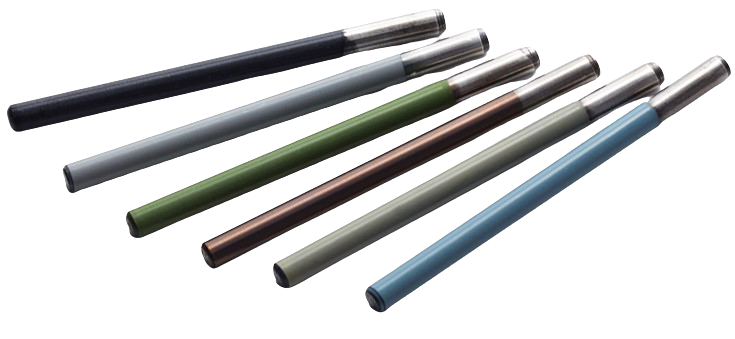

Quick Guide: See full table here

DR-95Z Grey: For complex profiles, contours, and ID coatings

DR-96 Green: Ideal for applications needing a green finish

DR-97 Lt Grey: Similar to DR95Z, but more durable for parts

DR-472 Blue: Blue finish variant with durability like DR97

DR-100 Black: Suitable for applications needing a black finish

DR-00 Clear: Transparent finish, max length of 24 inches

Polytetrafluoroethylene (PTFE) is a fluorpolymer designed for use in applications that require high temperature stability and durability in a non-stick finish, used as a release agent in thermal bonding and injection molding, reflow, and adhesive bonding processes.

RothGreaves Dry Release (DR) PTFE formulations are so smooth you’ll feel the difference. These lubricious dry release finishes can be applied to nearly any tooling that requires a high working temperature, and high release properties.

The cured finish is biocompatible and has passed USP Plastic Class VI testing and can withstand temperatures up to 600 Fahrenheit making it ideal for use in the manufacturing of medical devices and food contact products.

The superior durability and smooth finish places them amongst the best and most reliable release finishes available on the market today.

Leading the Way in PTFE Coating Processes

Quality, Precision, and Innovation in Every Step

Expert Quality Control

Our Quality Control technicians meticulously monitor every step of the process to ensure the highest standards in manufacturing our DR PTFE coatings.

High-Quality Ingredients

We use only the finest quality ingredients to guarantee that RothGreaves DR PTFE coatings are the best on the market

Precision and Consistency

Precision and consistency are key to maintaining the high standards of our RothGreaves DR PTFE Coatings

Diverse Coating Options

We offer a wide range of PTFE coatings, each tailored to meet specific industry requirements and applications

Innovative Coating Process

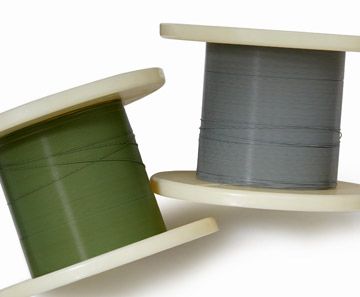

RothGreaves has perfected the process of coating wire in a reel-to-reel application for superior performance

Versatile PTFE Coatings

RothGreaves PTFE Coatings adhere to both simple and complex geometry parts, ensuring versatility and reliability

Medical and Food Grade PTFE Coatings FAQs

RothGreaves DR PTFE cured finish is biocompatible and has passed USP Plastic Class VI testing making it suitable for use in the manufacturing of medical devices and food contact products.

See Safety Data Sheets (SDS) below:

Do you have medical grade coatings?

Our coatings are medical grade and biocompatible according

to USP Plastics Class VI Certification.

Do you offer any coatings other than PTFE?

Our focus is providing PTFE coating services.

What color PTFE’s do you have?

Light grey, dark grey, blue, green, black, and clear.

What is your coating thickness?

Average .0003".

Will your coatings cover up scratches or blemishes?

Our coatings are capable of conforming to complex surface profiles and will cover minor blemishes.

What methods of sterilization can be used on medical parts?

Ethylene Oxide (ETO)

NOTE: These coatings are NOT recommended for use in implantable medical devices.

Which DR Coating Do You Need?

RothGreaves offers a range of proprietary DR PTFE finishes, including DR-95Z, DR-96, DR-97, DR-472, DR-100, and DR-00. Each formulation provides exceptional release properties and comes in different colors for quick and easy part identification.

Our superior release finishes are ideal for tooling used in medical device manufacturing, such as mandrels, hypotubes, core pins, and tipping dies.

PTFE Coating

Avg. Thickness

Coating Description

DR-95Z Grey

.0003" / Side

DR95Z has increased flowability and is recommended for parts with complicated profiles, challenging contours, sharp edges, as well as for interior ID coatings

DR-96 Green

.0003" / Side

DR96 is a color variant recommended in applications where a green finish is desirable

DR-97 Lt Grey

.0003" / Side

DR97 is a variation with similar properties to DR95Z but may provide increased durability on straight or slightly tapered parts

DR-472 Blue

.0003" / Side

DR472 is a color variant offered for applications where a blue finish is desirable and which may see increased durability similar to DR97

DR-100 Black

.0003" / Side

DR100 is a color variant offered for applications where a black finish is desirable

DR-00 Clear

.0001" / Side

DR00 is a coating without any color pigmentation, giving the material a neutral, transparent finish. Maximum length of 24"

* Please note that all RothGreaves DR PTFE formulas cure at 750 degrees Fahrenheit

Orders for RothGreaves DR PTFE Coatings require no minimum or maximum quantity for standard parts with a coating length of 72″ or less, and minimum of 200 ft for reel-to-reel coating. Lead times are competitive, most orders shipping in 1–2 weeks.

Call 1-952-404-2604 or click the link below to get a price quote and estimated delivery times.

GLOSSARY OF DR PTFE COATING TERMS

Abrasion: Wearing, grinding, or rubbing away by friction.

Additive: A substance added to a formulation in relatively small amounts to impart or improve desirable properties or suppress undesirable properties.

Alkaline Wash: Cleaning process that employs a high pH solution (caustic). A good choice for parts with little buildup of contaminants.

Aluminum Oxide: Hard particulate medium used in grit blasting to clean and roughen surfaces that are to be coated.

ASTM: American Society of Testing and Materials.

Average Particle Size: The average diameter of particles as determined by various test methods.

Binder: Tough polymer that acts as an adhesive to join elements of matrix coatings.

Buffing: Process of polishing a cured coating to improve release and low friction.

Bulk Density: The mass per unit of volume in powder form, including the air trapped between particles.

Burn-off: A method of removing a coating. Temperature is elevated above the degradation point of the coating and held there until the coating breaks down. (See surface preparation).

Burnishing: Process of polishing a cured coating to improve release and low friction.

Carrier: The liquid portion of a coating (solvent or water) in which solids are dissolved or suspended.

Coefficient of Friction: A number expressing the amount of frictional effect: static or dynamic.

Cold Flow: Tendency of plastic materials to migrate slowly under heavy loads and/or over time.

Compatibility: The capacity of different materials from different sources or of different compositions to be combined and applied so as to yield no visible or mechanically measurable differences in the cured film or application properties.

Conductor: Material that can support flow of electric current. Fluoropolymer coatings are normally insulators but can be modified with certain fillers and pigments to make them conductive.

Contact Angle: A means of quantifying the nonstick properties of a coating by measuring the ability of a liquid to wet its surface.

Corrosion: Process of metal decomposition (oxidation) in which metal ions are united with oxygen to form metal oxides. Fluoropolymer coatings provide excellent barriers against corrosion.

Cross-linking: Quality of thermosetting plastic resins in which polymer chains combine during the curing process. In general, the greater the cross-linking, the tougher and more chemically resistant the coating.

Cryogenic: Relating to very low temperatures.

Cure End Point: The point either during or following the cure schedule at which the coating film is determined to have developed specified properties.

Cure Schedule: The time/temperature relationship required to cure a coating.

Curing: Process of bonding or fusing a coating to a substrate with heat and developing specified properties in the coating.

Cut-through Resistance: A coating film’s resistance to penetration resulting from the combined application of sharp edges, heat, and pressure.

DFT: Dry Film Thickness.

Dielectric Strength: Ability of a coating to resist the passage of electric current.

Dip/Spin: Coating application technique in which small parts are placed in a basket that is lowered into a coating bath, then raised and spun to remove excess coating. An economical system for coating high volumes of small parts.

Dry (Solid) Lubricants: Solid materials such as PTFE, Molybdenum Disulfide, and graphite that have low coefficients of friction.

Edge Coverage: A coating’s ability to flow over, build, and adhere to sharp corners, angles, and edges.

Engineering Plastics: Plastic resins that have high-performance properties such as high temperature stability, hot hardness, abrasion resistance, and corrosion resistance.

ETFE (Ethylene Tetrafluoroethylene): A thermoplastic member of the fluoropolymer family. ETFE is noted for exceptional chemical resistance, toughness, and abrasion resistance.

FEP (Fluorinated Ethylene Propylene): A thermoplastic member of the fluoropolymer family. FEP has excellent nonstick and non-wetting properties.

Fillers: Pigments and other solids used to alter properties of coatings.

Flash Point: The lowest temperature at which a solvent will generate sufficient vapors to ignite in the presence of heat.

Flashing: A brief sub-cure (at lower temperatures than the final cure) to drive off solvents or carriers prior to full cure. This helps prevent bubbling or blistering.

Fluoropolymers: Family of engineering plastics containing fluorine, characterized by high thermal stability, almost universal chemical resistance, and low friction.

Friction (Dynamic): Resistance to continued motion between two surfaces; also known as sliding friction.

Friction (Static): Resistance to initial motion between surfaces.

Fusion: The melting and flowing of heated polymer particles to form a continuous film.

Graphite: A carbon-based dry lubricant that is preferred for high-temperature applications.

Grounding: Being electrically connected to the earth or having no charge.

Hot Hardness: Ability of a coating to retain hardness and wear resistance at elevated temperatures. Usually a characteristic of coatings based on thermosetting resin binders.

HVLP (High Volume, Low Pressure): A spray technique utilizing high pressure in combination with low air velocity to increase transfer efficiency and reduce air pollution.

Hybrid Resin: A combination of two or more common resins.

Intercoat Adhesion: A coating’s ability to adhere to previously applied films, including primers.

lbf: Pounds force, a measure of force, also expressed as “Kilo-Newtons” (KN).

Lower Explosive Limit (LEL): The lowest percentage at which organic particles suspended in air will ignite if a source of ignition is introduced. It is also referred to as minimum explosive concentration (MEC).

Matrix Coating: One in which some ingredients, such as the lubricant (PTFE), which is soft, are enveloped in others (the matrix, such as harder, more wear-resistant binders). Also referred to as “resin bonded coating.”

Melt Point: The temperature at which a polymer particle will begin to melt and flow.

Micro-inch: μ inch, a millionth of an inch.

Micron: μ, one micron, one millionth of a meter. Also expressed as μm or micro-meter.

Migration (of Lubricant): Characteristic of any lubricant which is under pressure to move away from the bearing area.

Noise Reduction: The absorption of sound vibrations. Fluoropolymer coatings form good noise dampening surfaces.

Oleophobic: Oil shedding.

Partial Cure: Process sometimes utilized when multiple layers of fluoropolymer coatings are to be applied. The first coat is incompletely cured; the second coat is applied and both are fully cured together. See Flashing.

Pencil Hardness: A value determined by measuring the relative hardness of a coating based upon the ability of the coating to resist penetration and gouging by pencil lead of varying hardness. The order of pencils from softest to hardest is 4B, 3B, 2B, B, HB, F, H, 2H, 3H, 4H, 5H, 6H, 7H, and 8H. The hardness rating of the coating is equal to the first pencil which does not penetrate and gouge the coating when tested from softest to hardest.

PFA (Perfluoroalkoxy Ethylene): Thermoplastic member of the fluoropolymer family of engineering plastics, one characterized by excellent release, chemical resistance, and toughness.

pH: An expression of the degree of acidity or alkalinity of a substance expressed as a number from 0 to 14. Neutrality is pH7. Acid solutions are less than 7 and alkaline solutions are greater than 7.

Phenolic: A resin or plastic, usually thermosetting, made by condensation of a phenol with an aldehyde and used for molding, insulating, coatings, and adhesives.

Phosphating: Surface pretreatment used on ferrous parts that provide a very thin crystalline film that enhances both corrosion resistance and adhesion.

Pigment: Finely divided, insoluble colored substance used to impart color to a coating.

Polymer Fume Fever: An illness characterized by temporary flu-like symptoms caused by inhaling the products released during the decomposition of fluoropolymers.

Post-cure: A second cure at high temperature to enhance specific properties such as release and non-wetting.

Postforming: Process of shaping parts after a coating has been applied and cured, a technique commonly used with stamped, blanked or spun parts.

Preheating: Warming of parts prior to application of a coating, recommended when adhesion is critical and when parts are being coated in humid atmospheres. In some cases, this technique can be used to achieve higher-than-normal film builds.

Preloads (for Fasteners): The “tightness” of a fastener, equal to the make-up energy applied minus the energy required to overcome friction at the fastener’s bearing surfaces and threads.

Pressure Spraying: Coating technique similar to siphon spraying, except that the coating is delivered from a pressurized pot to the spray nozzle under positive pressure. Generally used for high-volume production.

Pretreatment: Processes for cleaning and conditioning a substrate to be coated. Next to the choice of coating, this may be the most important factor in the use of high-performance coatings.

PTFE (Polytetrafluoroethylene): PTFE has the lowest coefficient of friction of any known solid and the highest operating temperatures of the fluoropolymers.

PVDF (Polyvinylidene Fluoride): High-molecular weight thermoplastic of vinylidene fluoride with excellent strength, wear resistance, and creep resistance.

Resistance (Electrical): The opposition offered by a coating to the passage of an electric current through it.

Sand Blasting (also Grit Blasting): The process of surface cleaning and roughening that provides a mechanical “tooth” to aid coating adhesion. Media include aluminum oxide, even crushed walnut shells. The medium must be chosen to match the substrate and the foreign material on the substrate to be removed.

Sintering: A process of raising the temperature of PTFE to the point at which PTFE particles soften and bond with each other.

Siphon Spraying: Most common technique for applying coatings, also known as “conventional air spray”. The coating is drawn from a reservoir into an atomizing air nozzle and propelled toward the surface to be coated.

Static Electricity: Buildup of stationary electrical charge on a coating powder or a coated surface.

Stick-Slip (Chatter): Unstable sliding condition in which movement of one part over another starts and stops, caused by temporary overcoming of static friction.

Storage Stability: The ability of a coating material to maintain uniform physical and chemical properties while in storage over an extended period of time.

Substrate: Any surface to be coated. This can include metals such as steel, cast iron, bronze, brass, aluminum, stainless steel, chromium and, with special precautions, nickel. Paper, most plastics, wood, leather, fabrics, and glass can also be coated.

Surface Appearance: The smoothness, gloss, and presence or lack of surface defects in a coating.

Surface Treatment: Conditioning the substrate before coating through grit blast, phosphate, etc. May include the removal of a coating (See Burn-off).

Tetrafluoroethylene (TFE): Monomer used as a chemical feedstock in the production of PTFE or Teflon®.

Thermoplastic Resin: A resin which will melt when heated and solidifies when cooled, and softens when reheated.

Thermoplastic: Plastic resin that softens when reheated and hardens when cooled.

Thermosetting Resin (Thermoset): A resin designed to undergo an irreversible chemical and physical change during a heat-cure schedule, i.e., a plastic resin that crosslinks during cure so that it does not soften when reheated.

Transfer Efficiency: The ratio of the amount of coating deposited on a substrate compared to the total amount directed at the part to be coated.

Upper Explosive Limit (UEL): The highest percentage at which organic particles suspended in air will ignite if a source of ignition is introduced.

Volatile Content: The quantity, expressed as a percent weight of a coating, that is lost under specified conditions of temperature and time.

Volatility: The readiness of a substance to change from a solid or liquid form to a vapor.

Wear: Deterioration by friction (abrasion, spalling, cutting, fretting).

Weight Solids: Expressed as a percentage, it is the amount of a substance which remains relative to the total weight, after all volatile components of the substance have been evaporated. The determination is usually hastened by heating the substance in a controlled environment.

Wrap: A characteristic of liquid and powder coatings in electrostatic application to adhere to areas of the substrate not in direct line of sight of the delivery system end point.

DR PTFE Coating Processing Capabilities & Tolerances FAQs

What tolerances can you hold on medical devices and wires?

In most applications, coating will add .0001" to each side of the uncoated tolerance of the mandrel.

How do you measure coating thickness?

Our standard method is with a laser micrometer.

What is the longest medical device wire you can coat?

The longest discrete length is 72". We also provide continuous spool-to-spool coating services.

Can you mask sections of medical device wires?

Yes.

Can you coat nitinol?

Yes.

Can you coat medical device springs?

Yes.

Can you strip off old coating and re-apply new?

Yes

What is normal surface preparation?

We offer several surface preparation options to ensure parts are clean and ready to coat properly. Oily or dirty parts will not coat well.

What are the operating temperatures of your coatings?

Less than 600 F for short runs and less than 500 F for extended runs.

Do you have a Quality Control department?

Yes.

Can you certify your coating under a certain military spec?

We provide a Certificate of Compliance for every order based on customer supplied specifications. This may or may not suffice.

Are you ISO approved?

No, we are not ISO certified although our quality practices allow us to supply coating services to a range of industries.

Supporting Medical Device Manufacturing Around the World

All Rights Reserved | RothGreaves