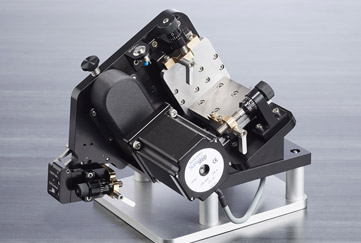

The innovative design of RothGreaves SideWinder machine allows direct-to-mandrel coiling at the diameter of the mandrel. This is perfect for reinforced catheter manufacturers. Depending on the diameter of the mandrel, we have two processes that are used to transfer the coil for a tight to the mandrel coil:

Method 1: direct transfer from a pre-coil and helical transfer directly onto a mandrel. The direct transfer operation pre-forms a coil from the deflection winder and then transfers it to the mandrel using a pitch guide. The coil is now on the mandrel at the diameter of the mandrel and ready for the next process step.

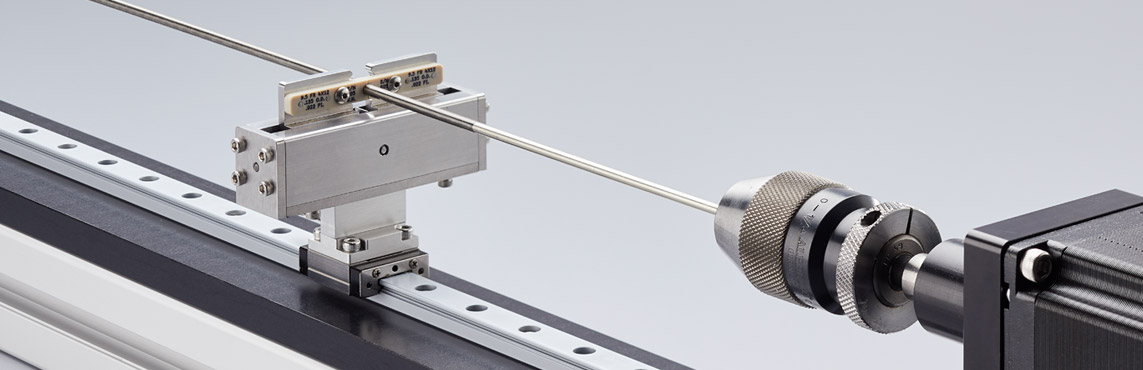

Method 2: the helical transfer process forms the coil and at the same time screws the coil onto the mandrel. After the coil is on the mandrel it can then be placed in the pitch setting guide (shown below and sold separately as an available option) to precisely set the pitch and lock the coil onto the mandrel. The Side-Winder Hybrid runs on our proprietary EasyWind™ software. The tooling for the pre-forming of the coil is specific to the wire profile and size. This coil winder can also be operated as a standard automatic machine as well as a manual load and unload machine making it the most versatile machine in our line of coil winders.

RothGreaves has developed our proprietary EasyWind software; this custom software was created for multi-pitch, multi-segment, multi-speed coil profiling. This is the most advanced software on the market today. EasyWind advanced features have recipe development and full security level control. All of our machines are operated by a CNC servo controller for extreme accuracy and reliability.

The Sidewinder Head precisely sets the pitch and locks the coil directly onto the mandrel.

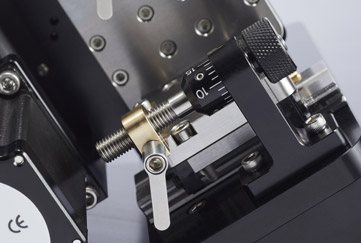

The Sidewinder Head’s Micrometer Adjustment feature provides, precision adjustment and minute fine tuning of the coil pitch.

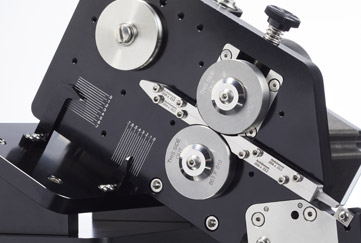

Different wire guides and rollers are manufactured to match the specific size and profile of the wire being coiled.

When using the helical transfer process, the Pitch Setting Guide is used after a helical transfer to set an accurate pitch and coil seating.

6000 Series SPECS:

- CE CERTIFIED

- Dimensions: 129″ L x 29″ W x 38″ H

- Chuck-to-chuck length: 96″

- Power requirements: 208-240 VAC, Single Phase, 50/60 Hz, 10 Amp

- Pneumatic requirements: 80 psi @ 3.0 cfm (5.0 if hot air torch option is installed)

- Servo motors/Drive amplifiers: Spindles (2) – 400 watt, Carriage (1) – 750 watt

- Winding speed max: 6000 rpm

- Controller type: CNC multi-axis servo controller

- Operating System: Microsoft Windows 10

- Manual jog controller: Pendant with joy stick operation all axis

- Operating Software: EasyWind™

- Interface: 17″ touch screen monitor and track ball keyboard

- Wire tensioning: Electronic (available in options)

- Arbor tensioning: Pneumatic or actuator control (available in options)

- Tailstock Chuck sizes: 1/16″, 1/8″, 1/4” (available in options)

- Headstock Collet sizes: 0.010″ to 0.180″ (available in options)

- Safety features: Light curtain with surround or door with surround (available in options)

- Multi-filar options are available for this model